The Court Company’s squash courts include the best products for transforming your space to a tournament-level squash court. Whether you need a squash court for an athletic club, for your company, or for your residential project, The Court Company can help you throughout the planning and construction process.

The Court Company designs and builds first class squash courts

The Court Company’s team members will work with you on every step of the court construction process. We will walk you through the steps of court construction as well as determine the best finishes for the interior of your court while maintaining the expectations of squash players.

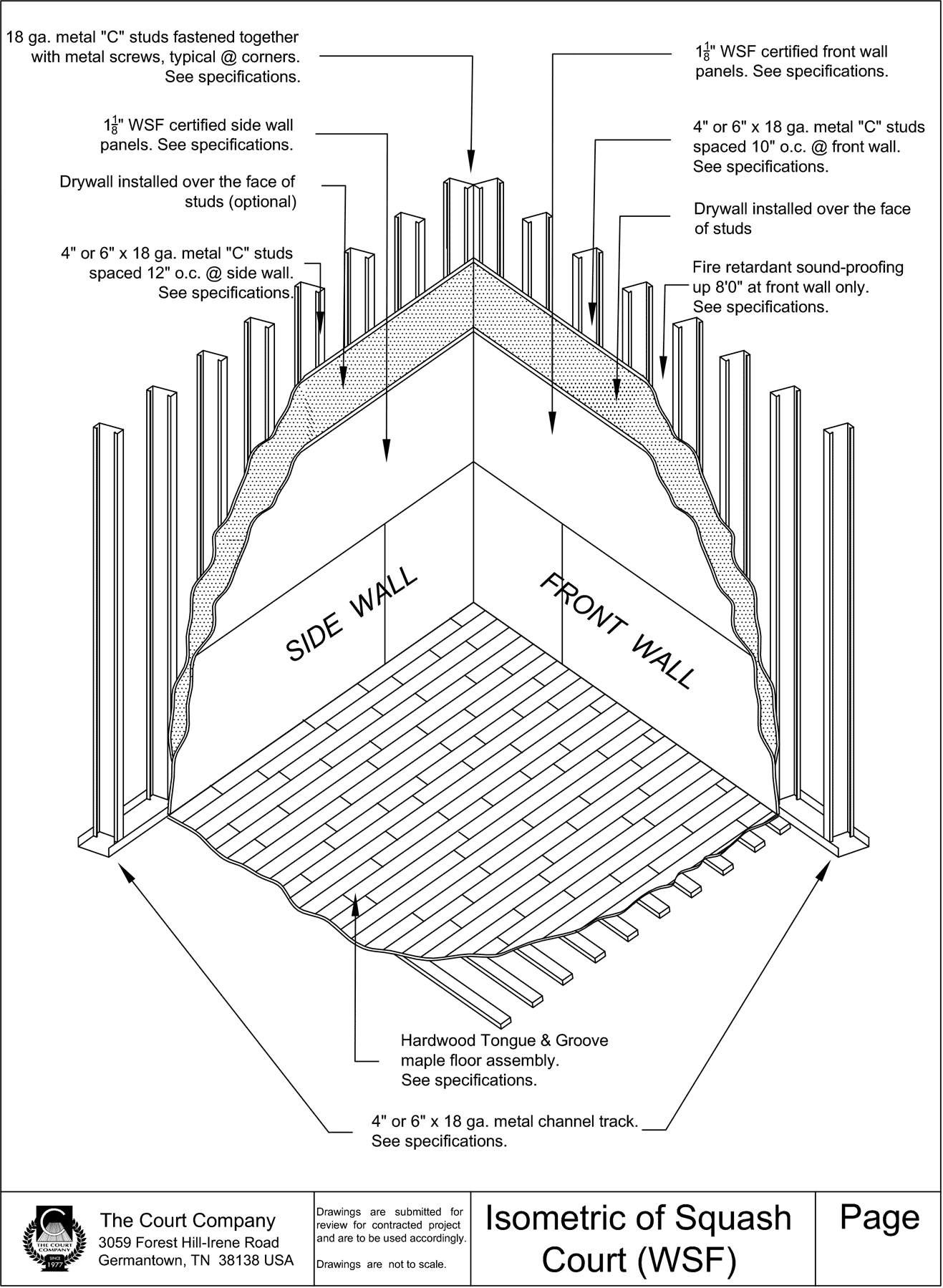

Squash Court Panels

We build our courts around the expectations of the the World Squash Federation (WSF) with the court being 21’0″ wide x 32’0″ long. Even though the court height needs to be a minimum of 18’6″ high, many projects will elect to stop the panels at the play line heights and finish above these areas with drywall. With the exception of any glass in the court, the playing surfaces of the court are made of wood. The finished wood surface provides uniformity for ball rebound and play. Our squash courts are designed for heavy use with pre-finished panels which provide a cost efficient and professional system. Unlike plaster systems, our panels never chip or crack and never need to be painted.

The 4’0″ x 8’0″ tongue and groove panels are built with a high pressure laminate; this is the thickest laminate available for court use. The high density core and surface gives the panel the structural stability needed for squash play. Our panel system is stronger and more durable than other systems. The playing surface of the panel is a white velvet finish used essentially for aesthetics and proper ball reaction. The panels are machined to our exact specifications with tolerances of ±1/32″.

The panels for a squash court are 1-1/8″ thick on all walls. Typical squash courts stop the panels at the playing lines at the front and side walls, but if you want the panels to extend up to the ceiling or if you want panels on the ceiling, that is not a problem. Racquet and ball marks can be easily wiped clean with common household cleaners.

Steel Stud Framing & Drywall

Typical court framing consists of 18 or 16 gauge galvanized steel with varying sizes of 4″ to 6″ depending on the location and design of courts. Wood framing is also acceptable as long as the framing is straight and plumb and does not twist or bow. It is recommended to install a layer of drywall or plywood at least behind the front wall panels (ideally at all paneled walls). If the panels are stopping at the play lines, many certified squash courts will install drywall behind the panels from floor to ceiling – not only to help the walls feel more dense, but to also provide a finished surface and visible boundary area above the play lines.